MULTI DIRECTION DYNAMIC CYCLIC SIMPLE SHEAR

Product Code : MDDCSS

| Key features | Benefits to the user |

|---|---|

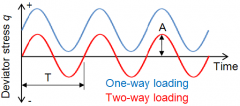

| Test control: | Test control allows specification of amplitude of shear stress/strain as well as direction. |

| Direction of shear and pattern of shear rotation from zero degrees can be defined: |

|

| Teflon coated rings: | K-zero conditions ensured by use of 1.1mm high, low-friction, PTFE coated rings. |

| 6 Axis Loadcell: | Highly accurate internally compensated measurement of all loads. |

| Independent axis control: | Each axis can be load or displacement controlled. |

| Local strain LVDT’s for both shear directions: | Highly accurate strain measurement. |

| Pressure control: | Confining pressure up to 1MPa is applied by water and controlled using a Pneumatic Controller (GDSPPC) through a direct air/water interface within the cell. A second pressure controller is used to apply back pressure. |

| Pore water pressure transducer: | Highly accurate measurement of pore water pressure in all stages of testing. |

| Actuators |

3 x electro-mechanical, high accuracy, encoder controlled. |

|---|---|

| Dimensions |

2.3 x 0.9 x 0.9m |

| Load Range (kN) |

10 normal force, 5 on each shear measurement (y and z) |

| Operating Frequency (Hz) |

1 |

| Sample Sizes |

50/70/100 diameter (other sizes on request), height 20 to 40 |

| Weight Approx (kg) |

650 |

Enquiry:hkmarketing@epc.com.hk

Enquiry:hkmarketing@epc.com.hk