Description

Introduction

This machine has been specifically designed to suit the requirements of Central and Commercial laboratories of the construction industry and Civil engineering in general. This universal tester, in fact, can be used for tensile tests on steel re-bars up to 40 mm dia., flats up to 35x75 mm, and compression tests on standard concrete specimens. It can also be used, with the appropriate accessory, for transverse and bending test on steel, flexural tests on concrete beams and general compression tests. Specialò accessories are also available for testing steel strands and electro-welded steel screen.

All the control functions are managed from a standard keyboard and mouse. The frame differ substantially from the old traditional models because of the originality of the design as for example the remote control displacements and gripping systems. The software include a complete suite of programs: tensile, bending, flexure and compression tests.

Once the specimen has been placed in the machine (using accessories if required) and the specimen data introduced, the test is run completely automatically at the press of a button up to the printout of the test certificate and the storage of the test data.

Machine frame, cylinder assembly, load cell

- Steel base with rigid frame housing the lower grippers

- Piston/Cylinder assembly mounted on the top of the rigid frame. Load cell incorporated in the piston.

- Mobile frame consisting of four high tensile strength columns, upper crosshead directly connected to the piston, intermediate crosshead with compression platen and lower crosshead housing the upper grippers.

- Hydraulically operated gripping system and vertical adjustment by two independent auxiliary cylinders controlled by the push button panel. This unique feature make the machine extremely easy to operate enabling one man to perform the test in a very short time.

- Crosshead displacement controlled by the use of a bi-directional encoder.

Control console

- The lower section houses the hydraulic assembly which include: Hydraulic pump, Proportional valve, Hydraulic valves, Heat exchanger to control the oil temperature and the Oil tank.

Grippers

- Three sets of standard grippers supplied with the machine, for rounds and flats, plus two sets of grip liners to provide maximum bearing and holding surface for specimens of all sizes.

Safety features

- Pressure switch, which automatically stops the machine when the oil pressure goes over the maximum permitted level.

- Max travel limit switch to stop the mobile frame at its upper position.

- Software feature which stops the machine when the maximum load is reached.

Hardware

The upper section of the control console houses the electronic card for the control of all functions, having the following specifications:

- A/D converter resolution 1/20000

- No. 4 outputs for electrovalves

- Analogical output for load and strain control:12 bit

- Load cell input

Software

The machine can be used either in the manual or in the automatic mode to perform:

- Tensile test on steel reinforcing bars conforming to EN 10002 and ASTM A370

- Tensile tests in general, flexural (transverse) and bending test on steel conforming to ASTM E290, UNI 564.

- Flexural tests on concrete beams conforming to EN 12390-5

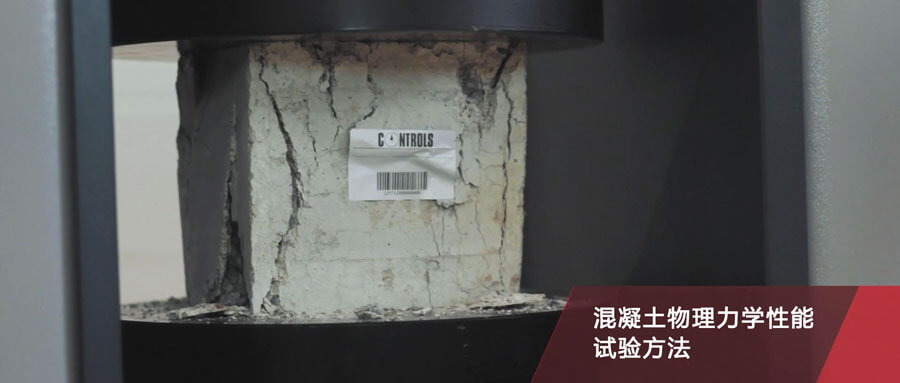

- Compression tests on concrete specimens conforming to EN 12390-3

Standard outfit

The machine is supplied complete with:

- No. 3 sets of grips for round specimens up to 40 mm dia. and flat specimens up to 70 mm wide and 35 mm thick and two sets of grip liners.

- No. 1 set of foundation bolts, 1 service spanner, instruction manual, PC and colour graphic printer

Enquiry:hkmarketing@epc.com.hk

Enquiry:hkmarketing@epc.com.hk