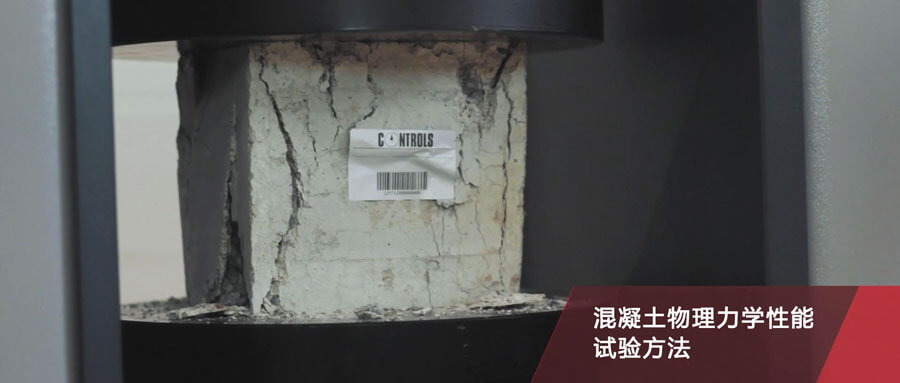

Description

AUTOMAX PRO-M Power Control System fitted with superior hydraulics can also perform, in addition to standard failure tests, the Modulus of Elasticity Determination tests, Characterizations of Fiber Reinforced Concrete (FRC) under displacement-control and tensile tests on steel specimens

AUTOMAX PRO-M introduces new features and capabilities that will revolutionize the operations of any progressive construction quality testing laboratories.

LinkLAB is CONTROLS’ new proprietary Laboratory Connectivity Package.

It allows your AUTOMAX PRO-M to be a connected part of your laboratory infrastructure by taking inputs from any number of ancillary measuring systems and devices increasing efficiency and eliminating transposing errors.

Technical Specifications

AUTOMAX PRO-M AUTOMATIC POWER AND CONTROL SYSTEM

Hydraulics

- DC motor, 720W, 50-60Hz

- Maximum working pressure 700 bar

- Load/unload electrovalve for test execution via display/PC and automatic stop at specimen failure

- Active control of up to 4 frames by selection via display/PC (third and fourth frame as option). See accessories.

- ES Energy Saving technology to reduce the power consumption and enable silent operation

- Flow-sharing technology to perform loading and unloading cycles at controlled rate

Hardware

- 524,000 points high-resolution/stability analog channels

-

6 channels to be factory configured:

- 2 channels for load sensors

- 2 channels for load or displacement/strain sensor

- 2 channels for displacement/strain sensors

- Control frequency 250 Hz

- Sampling frequency 250 Hz

- 7”, 800 x 480 pixel, 16 M colors, icon-driven capacitive sensing touchscreen graphic display

- Unlimited storage capacity for test data on internal 16 GB SD card

- USB port for test data storage on external USB memory stick and for firmware upgrade

- Ethernet port for PC / Internet /network communication

- Optional integrated graphic printer including Load-Time plot (for standard failure tests)

- RS 232 port for data downloading in ASCII format

Firmware

- Execution of compression, flexure, indirect tensile, ACV tests, Elastic Modulus, Poisson Ratio Determination plus Displacement-controlled tests (with 50-FW/DC) and tensile tests (with 50-FW/UTS) in automatic mode with test speed controlled by a closed-loop PID system.

-

Simultaneous display of:

- load, stress, actual load rate, load / time graph in standard failure test

- load, stress, strain, stress / strain graph in Elastic Modulus and Poisson ratio tests

- load, displacement, stress / displacement in displacement controlled tests (with 50-FW/DC)

- load, stress, displacement and % elongation (crossbeam), displacement and % elongation (extensometer, if connected), stress/%elongation graph in tensile tests (with 50-FW/UTS)

- Saving of the specimen failure type (to EN or ASTM) in concrete compressiont tests results

- Automatic performance of Elastic Modulus tests according to the main International Standards with automatic calculation of tests results

- Execution (with 50-SW/DC) of displacement controlled tests on beams, notched beams, round or square slabs

-

Execution (with 50-FW/UTS) of automatic tensile tests with:

-

Control up to yield by:

* Stress (method B to EN 6892-1)

* Strain by using extensometer (method A1 to EN 6892-1)

* Strain by using crosshead (method A2 to EN 6892-1) - Control after yield by grips' separation

- elaboration of tension test results: ReH, ReL, Rp, final elongation, etc. conforming to EN ISO 6892-1 and EN 15630-1

-

Control up to yield by:

- Download data to internal printer (optional) or to PC via RS 232 port or to USB memory stick

- PC / network communication via Ethernet

- Multi-coefficient linearization of the calibration curve for better accuracy at low loads thus avoiding the use of a second pressure transducer

- Recording facility for up to 9 test profiles for each channel including: type of test (e.g. compression, flexural, splitting, elastic modulus, displacement control, tension), specimen size and shape, test speed and other general information. Each one of the recorded test profiles can be recalled automatically to save time.

- Improved PID algorithm and multi PID selection. Up to three different PID settings can be tuned for each channel for a variety of materials (e.g. cylinder with neoprene pads, low strength specimens) and test methods (e.g ACV, flexure, elastic modulus, displacement control)

- Compatible with the newly released DATAMANAGER software, E-Module, D-Control and UTS software packages, tailored for construction material testing laboratories, for remote control, real-time data acquisition and results calculation.

- Peripheral devices integration with Link-LAB

- Automatic load measurement verification procedure, by connecting suitable load cells and our digital readout unit to PC

- Language selection (including Cyrillic and Chinese)

- Unit selection (kN, ton, lbf)

- USB port for firmware upgrade and safe backup of the original configuration data (PID, calibration, etc.), in case of loss and/or data corruption. The restore of the machine to the factory settings is easy avoiding the need of any technical support.

Phisical specifications

- Overall dimensions: (hxlxd) 1292x350x450 mm

- Weight approx .: 80 kg

Enquiry:hkmarketing@epc.com.hk

Enquiry:hkmarketing@epc.com.hk