Description

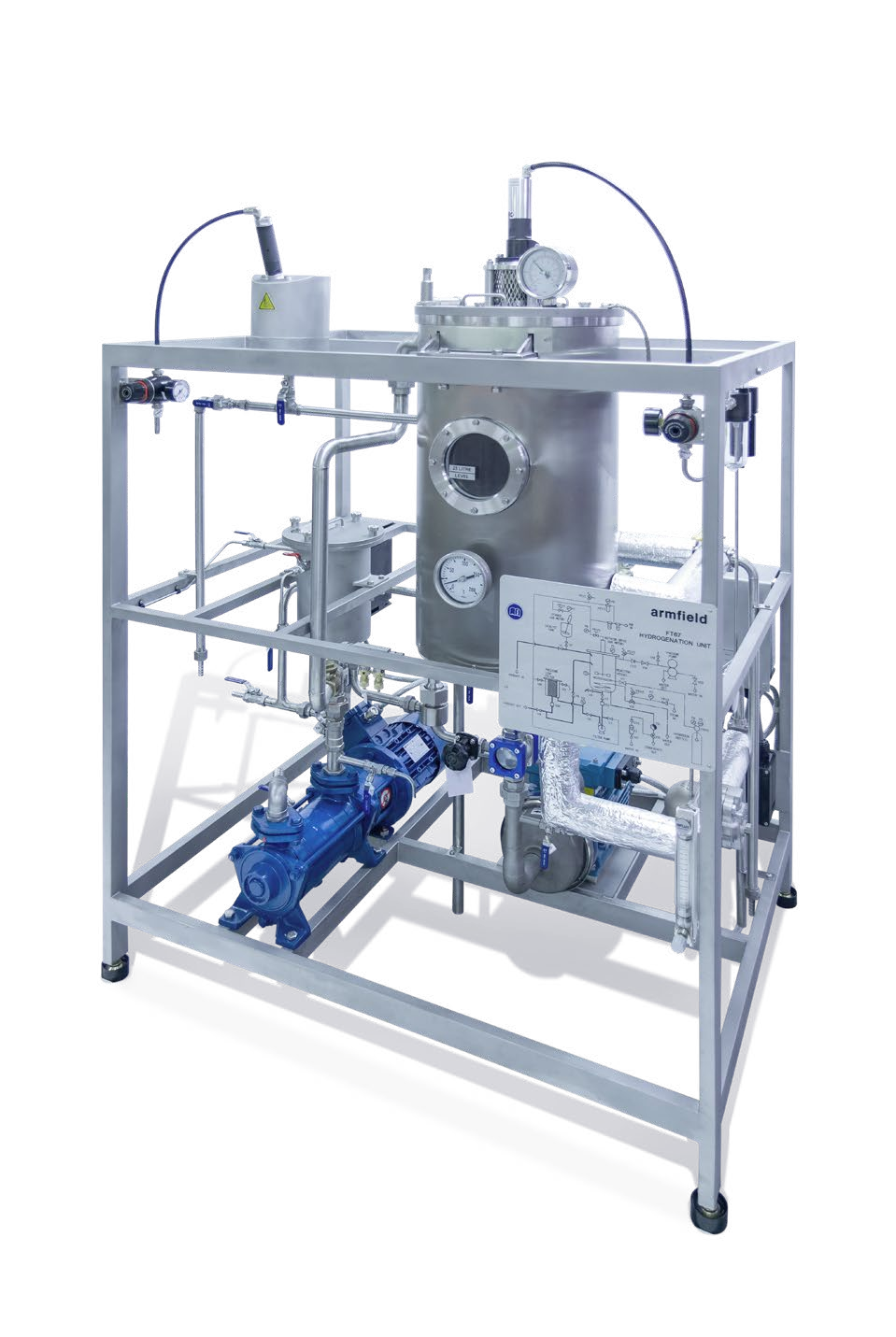

The main processing vessel is situated in a floor-standing stainless steel framework, which also houses a catalyst mixing tank, filter pump,

pressure leaf filter and vacuum pump. All equipment in contact with the process fluid is manufactured from stainless steel.

The hydrogenation vessel has a batch capacity of 25 litres.

It is a vertical cylindrical vessel, which incorporates a cooling/steam heating coil, hydrogen gas sparge ring, variable speed turbine agitator and baffle arrangement.

The hydrogen addition cycle results in an exothermic reaction and maintenance of the operating temperature is achieved by

circulating metered cooling water through the submerged cooling coil, which removes the excess heat from the reaction.

Initial heating to the reaction temperature is by steam, also in the immersed coil. A steam pressure control station enables pressures of up to 10.0 bar on the coil so that process temperatures of up to 180˚C can be achieved.

The turbine agitator is driven by a pneumatic motor through a mechanical seal in the lid of the vessel. Rotational speed is varied by adjusting the pressure of the compressed air driving the motor.

A maximum speed of 2500 rpm* can be achieved. The propeller mixer in the catalyst preparation tank is also driven by pneumatic motor and is capable of rotating at speeds up to 850 rpm*. Pneumatics are used

as the motive force as the presence of hydrogen gas requires minimal use of electrical components. Only the filter charge pump and the liquid ring vacuum pump are driven by electric motor.

The centrifugal filter charge pump enables efficient filtering of the catalyst from the oil by the pressure leaf filter, which is a reusable filter requiring no replacement of the filter element. If necessary, filter aid in the form of a diatomaceous earth can be mixed in the catalyst tank and added to the oil charge prior to filtering.

The process vessel and filter are designed fully in accordance with the BS 5500 code for pressure vessels. Vacuum levels of 65 mbar are achieved in the reactor vessel by the liquid ring vacuum pump.

Reduced system pressures are necessary to prevent oxidation during the heating cycle and assist in the removal of any water present in the oil. Also, the suction pressure is used to charge the vessel with oil and for the addition of catalyst and filter aid.

Technical specifications

All electrical equipment used on the unit is scheduled flameproof suitable for use in a zone 1 area, which is an area in which an explosive gas air mixture is likely to occur in normal operation. Due to the use

of hydrogen gas, the Hydrogenation Unit must be installed in an area designated as safe.

Relevant local regulations regarding the operation of this type of equipment must be adhered to.

Hydrogenation vessel

Total volume

25 litres

Cooling/heating coil surface area

0.08m²

Maximum working temperature

180˚C

Normal working pressure

0.7bar and 65mbar

Maximum working pressure

2bar

Agitator drive

pneumatic motor/gearbox

Maximum speed

2500rpm

Catalyst tank

Volume

4.0 litres

Stirrer

pneumatic drive, to 850rpm

Filter pump

Type

centrifugal

Impeller

closed

Capacity

100 l/m @ 2.75 bar

Liquid ring vacuum pump

Capacity

66.0m³/hr

Sealant

water

Sealant flow rate

6.0 l/m

Normal operating pressure

65mbar

Pressure leaf filter

Material

stainless steel

Filter volume

3.8 litres

Filter cake capacity

1.0 litre

Filtering area

0.09m²

Filter screen

110 mesh (0.3mm wire)

Maximum pressure

3.0 bar

Overall dimensions

Length

1.25m

Width

0.95m

Height

1.85m

Packed and crated shipping specifications

Volume

2.5m³

Gross weight

500Kg

Enquiry:hkmarketing@epc.com.hk

Enquiry:hkmarketing@epc.com.hk