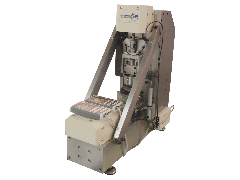

GDS SHEARBASE SYSTEM

Product Code : GDSSS

To see a comparison table of selected GDS shear products, click on the link,

| Key features | Benefits to the user |

|---|---|

| Desktop apparatus: | This desktop apparatus comes with built in controllers, resulting in a small footprint of just H x 660mm, L x 660mm, D x 220mm. |

| Runs from mains electricity: | The GDSSS comes with an integrated power supply, meaning the only laboratory service required for the system is mains electricity (110Vac – 240Vac). |

| No requirements for compressed air or hanging weights: | The apparatus is a fully self contained, no lifting of heavy hanging weights. |

| Normal (axial) and shear forces are applied using GDS electro-mechanical force actuators: | The use of GDS force actuators makes the system very flexible, each axis can be controlled in displacement (strain or velocity) mode as well as load control. |

| Topcap fixity: | Topcap fixity is assured through a system of crossed roller linear guides to minimise topcap rocking during shearing. |

| Sample preparation and topcap support apparatus: | Simple shear sample preparation and insertion into the system is made easy by using the included sample preparation and topcap support apparatus. This ensures that no load is applied to the sample during preparation and insertion. |

| Closed loop feedback: | Axial and shear load readings are controlled under closedloop feedback. |

| Fully automated: | For direct shear, once the shear gap has been set, the test can complete with no further user intervention. For simple shear, once the top-cap is docked all consolidation and shearing stages can proceed with no further user intervention. |

| Load Range (kN) |

2.5, 5, 10 |

|---|---|

| Sample Sizes |

up to 100mm |

Enquiry:hkmarketing@epc.com.hk

Enquiry:hkmarketing@epc.com.hk